|

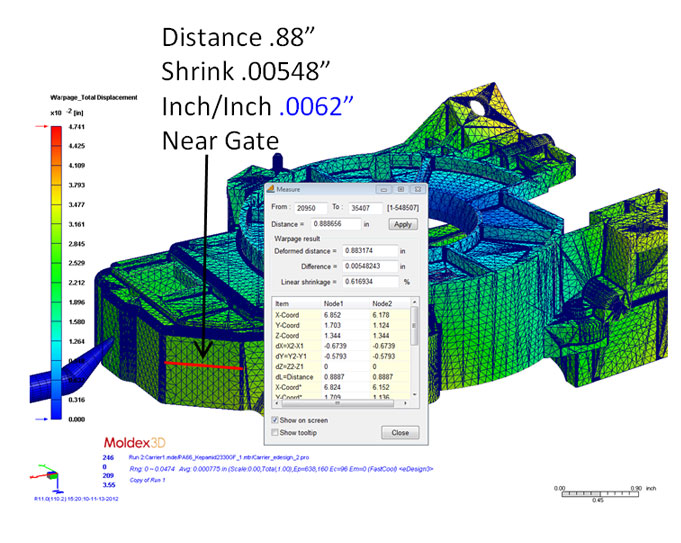

Shrinkage and Warpage Analysis

|

|

|

- Adding Metal or Plastic Part Inserts

- Identifying Thermal Results of the First and/or Second Shot of Plastic Material

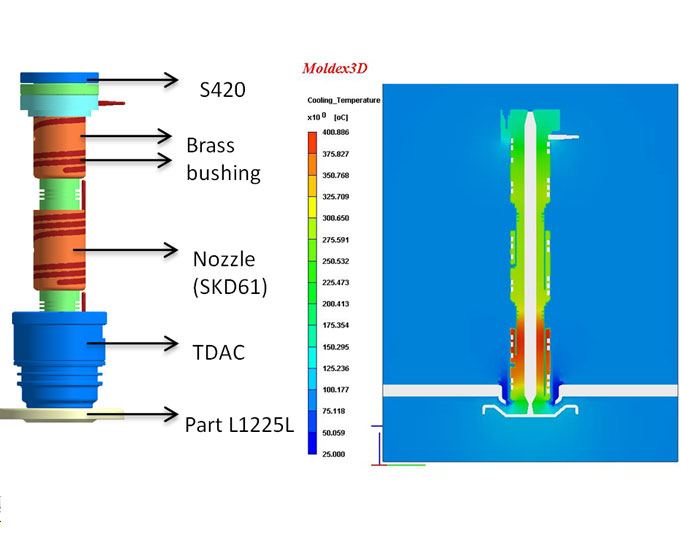

- Adding Mold Component Inserts

- Identifying Thermal Tool Insert Results

- Reducing the Cycle Using Highly Conductive Mold Metals

- Identifying the Displacement of Terminals

- Identifying the Differences of Hot or Cold Inserts

- Performing Two-Shot Plastic Injection Molding and Overmolding

|

- Optimizing Process Conditions

- Identifying Potential “Blow Out”

- Identifying Skin Ratio

- Improving Cycle Time

- Reducing Stress and Warping

- Eliminating Sink Marks and Voids

- Minimizing Material Usage

- Reducing Part Weight

- Increasing Part Strength

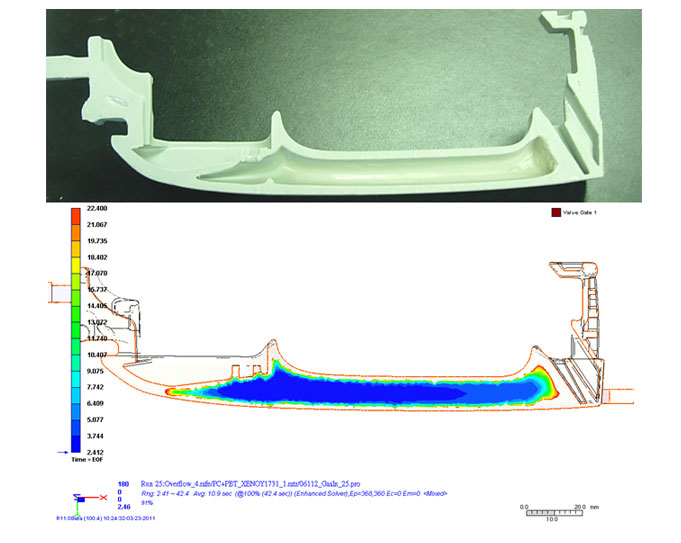

- Adding Overflow Tabs

|

Contact us today for more information about our plastics engineering services, including mold cooling analysis and co-injection molding.

Ready to improve part quality and reduce cycle time?

Get a fast, engineer-reviewed quote for Mold Filling, Packing, or Cooling analysis.