Capabilities

- Simulates insert molding, overmolding, and multi-shot sequential molding processes

- Evaluates melt flow and flow pressure around plastic or metal inserts

- Evaluates the effect of insert material in mold-cooling performance and insert temperature distribution in the molding process

- Evaluates the interaction and mechanical property (i.e., fiber orientation) effects of part inserts and parts in warpage

- Detects thermal degradation problems of plastic components reheated by the hot melt flow

- Predicts temperature variations within plastic part inserts during the molding process

- Employs parallel computing technology to enhance computation speed and extend analysis capability

|

Capabilities

- Models fiber length, diameter, and concentration in evaluating fiber orientation, shrinkage, and warpage

- Predicts 3D fiber orientation and thermomechanical property distributions

- Reduces anisotropic shrinkage of short-fiber reinforced thermoplastics

- Controls part strength of short-fiber reinforced thermoplastics

Results

- D Fiber Orientation Prediction Using the Folgar-Tucker Model

- Elastic Modulus Distribution Prediction

- Coefficient of Linear Thermal Expansion Distribution Prediction

- Composite Property Calculations Based on Well-Accepted Short-Fiber Reinforced Models

- Production of Anisotropic Thermomechanical Property Output Through the FEA Interface

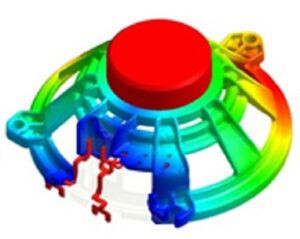

Multicomponent molding (MCM) is one of the best ways to diversify the development of plastic-molded product fabrication. MCM uses true 3D technology to simulate insert molding, overmolding, and multi-shot sequential molding. It also has explicit analysis capabilities to help you analyze the interaction behavior of different components while further optimizing plastic product design. In addition, this software product predicts warpage caused by various factors, including, but not limited to, the following:

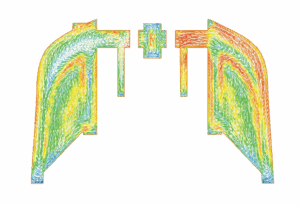

Multicomponent molding (MCM) is one of the best ways to diversify the development of plastic-molded product fabrication. MCM uses true 3D technology to simulate insert molding, overmolding, and multi-shot sequential molding. It also has explicit analysis capabilities to help you analyze the interaction behavior of different components while further optimizing plastic product design. In addition, this software product predicts warpage caused by various factors, including, but not limited to, the following: This software product simulates 3D fiber orientation and calculates process-induced anisotropic thermomechanical properties for fiber-reinforced plastic parts. It accurately predicts warpage so you can reduce costs and improve the strength of your manufactured plastic parts. Fiber also lets you control anisotropic shrinkage for fiber-reinforced parts. In addition, it helps you visualize and analyze mechanical properties caused by fiber orientation.

This software product simulates 3D fiber orientation and calculates process-induced anisotropic thermomechanical properties for fiber-reinforced plastic parts. It accurately predicts warpage so you can reduce costs and improve the strength of your manufactured plastic parts. Fiber also lets you control anisotropic shrinkage for fiber-reinforced parts. In addition, it helps you visualize and analyze mechanical properties caused by fiber orientation.