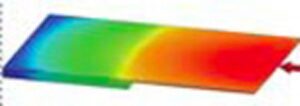

Melt Front Time: 99%

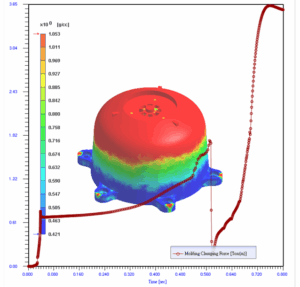

Tonnage Reduction

Moldex3D MuCell® Analysis

The microcellular injection molding (MuCell®) process can mass-produce parts with complex geometries and excellent dimensional stability. It is used in various applications, such as automobiles and electronic/electrical, construction, and outdoor products. In this process, a supercritical fluid, usually nitrogen or carbon dioxide, is mixed with a polymer melt to create a single-phase polymer/gas solution. This is then injected into the mold cavity, where bubbles form within the product.

Some of the benefits of this technology include lower injection pressures, lower temperatures, shorter cycle times, less energy, and less material. Despite these, the addition of supercritical fluid brings the complexity of material morphology, flow behavior, and product surface quality. These hamper the development and broad acceptance of the process.

Solutions and Benefits

MuCell® employs the fundamental physics of bubble nucleation and growth to model this complex process realistically. It lets manufacturers and design engineers visualize a microcellular injection molding process and understand its complex filling behavior and foaming mechanism. In addition, it reveals the mystery of microcellular injection molding while providing design validation, time-to-market optimization, and development cost reduction.

Moldex3D MuCell® Solves Tough Problems

Challenges

- Bubble number and size distribution depend on process conditions and are vital to the success of MuCell® product development.

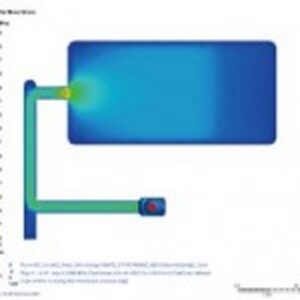

- Weld line and air traps play a crucial role in optimizing gate numbers and locations.

- Part geometry, part wall, and rib thickness design rules differ from the conventional injection molding process.

Solutions

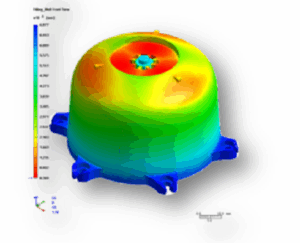

- Moldex3DMuCell® provides bubble size and number distributions and predicts the filling pattern, weld line, and weight reduction involved in the microcellular injection molding process.

- Moldex3DMuCell® evaluates the benefits of using the microcellular injection molding process, including dimensional stability and efficient energy usage. It also provides insight into part design, mold design, and operation optimization conditions.

*MuCell® is a registered trademark of Trexel Inc.

Plastics (i.e., polymeric) fluids are often called viscoelastic fluids because they have viscous and elastic properties. The viscoelastic effect depends on different temperatures and shear rates. During the filling stage, the flow field varies severely, and the viscous property of the polymer determines flow behavior.

Plastics (i.e., polymeric) fluids are often called viscoelastic fluids because they have viscous and elastic properties. The viscoelastic effect depends on different temperatures and shear rates. During the filling stage, the flow field varies severely, and the viscous property of the polymer determines flow behavior.