Cool Analysis

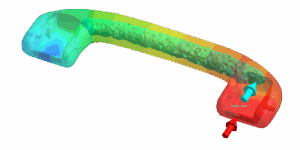

This is an efficient tool based on true 3D technology that analyzes the following aspects of the design phase:

- Mold Temperature

- Cooling Channel Layout Efficiency

- Required Cooling Time

Cool is also a troubleshooting tool that detects possible mold cooling system defects, such as:

- Unbalanced Cooling

- Hot Spots

- Prolonged Cooling Time Due to Poor Cooling Efficiency

In addition, it can accurately evaluate cooling efficiency to optimize your cooling system design and reduce cycle time.

Capabilities

- Predicts temperatures within parts, runners, cooling channels, inserts, etc.

- Evaluates the efficiency of your mold cooling system design, including cooling circuits, inserts, mold bases, heating rods, etc.

- Minimizes unbalanced cooling problems

- Determines required cooling cycle times

- Optimizes your mold cooling system design to achieve optimum cooling efficiency within the shortest cycle time

- Uses a fast and easy cooling analysis solution called “Mesh-Free eDesign FastCool” to validate mold cooling system designs

- Simulates multicomponent molding processes, including insert molding and multi-shot sequential molding (Note: The MCM module is required for this.)

Results

Part Cooling Analysis

This feature involves calculations of the following:

- 3D Temperature Distribution Within Parts, Runners, and Part Inserts

- Frozen Areas

- Heat Transfer Rate and Heat Load

- Required Cooling Time

Mold Base Cooling Analysis

Included in this analysis are calculations of the following:

- Solid Temperature Distribution Within Mold Bases, Inserts, and Cooling Circuits

- Cooling Circuit Efficiency

- Part Insert Effects (Note: The Moldex3D MCM module is required for this.)

- Mold Insert of Different Materials, Including Beryllium Copper

- Heating Rod Effects

Cooling Channel Network Analysis

This feature involves an analysis of the Reynolds number along each cooling channel and calculations of the following:

- Coolant Temperature Along Each Cooling Channel

- Pressure Drop of Each Cooling Channel

Auto-Set Cooling Time Analysis

With the help of this feature, you can easily estimate the required cooling time of your systems.

Coupled Flow-Pack-Cool Analysis

This feature lets you incorporate the heat flux results from flow and pack analyses for cooling calculations. It also improves the accuracy of flow, pack, cool, and warp analyses.

Transient Cooling Analysis

Aside from helping you predict the temperature variation history of your system’s mold cooling stage, this feature supports the following:

- Variotherm Process Simulation

- RHCM Process Simulation

Warp Analysis

This software product lets you perform true 3D warpage analysis on thick plastic parts and parts that have extreme thickness changes. It does this based on the filling, packing, and cooling analyses conducted by the Flow, Pack, and Cool products.

This software product lets you perform true 3D warpage analysis on thick plastic parts and parts that have extreme thickness changes. It does this based on the filling, packing, and cooling analyses conducted by the Flow, Pack, and Cool products.

Warp helps improve the quality of your plastic parts while optimizing their design. It also predicts the anisotropic shrinkage and warpage of fiber-filled material by incorporating fiber composite theories and the fiber orientation results from Fiber. In addition, it links to I2 modules to interface with structural analysis software.

Capabilites

- Evaluates final part shape before actual molding

- Evaluates single-cavity and multi-cavity molds

- Evaluates unbalanced cooling effects on warpage

- Evaluates volumetric shrinkage effects on warpage

- Evaluates molecular and/or fiber orientation effects on warpage (Note: The MCM module is required to predict fiber orientation.)

- Evaluates in-mold constraint effects on warpage

- Evaluates mold base thermal deformation effects

- Evaluates thermally induced residual stress

- Queries any two points to determine the linear shrinkage ratio between two locations

- Defines an arbitrary reference plane for easy deflection measurement

- Separates total displacement into x-axis, y-axis, and z-axis displacements to show the deformation in each direction

- Exports warpage and inverse warpage shapes in STL or Mesh format for further study

Results

Part Warpage Analysis

This analysis involves calculating the final plastic part’s shape due to material shrinkage as the temperature and pressure change from process settings to room conditions.

Residual Stress Analysis

When a manufactured plastic part is ejected, it shrinks and deforms into an equilibrium shape. At this point, the remaining stress inside it is called process-induced residual stress. Moldex3D Warp lets you calculate the residual stresses developed during the molding cycle, including temperature and pressure distribution effects, material orientation, and geometric features.

Material Anisotropic Analysis

Anisotropic properties are calculated based on the material orientation tensors obtained from flow analysis. These properties are then transferred to general structure CAE software for a part structure analysis involving process-induced properties.

In-Mold Constraint Effect Analysis

Before a plastic part is ejected, the deformation of warpage has been developed inside the mold. However, the mold’s rigidity prevents the part from shrinking and deforming freely. Moldex3D Warp lets you calculate the warpage induced by in-mold constraint to enhance the accuracy of its analysis.

Gas-Assisted Injection Molding Analysis

Gas-Assisted Injection Molding (GAIM) visualizes 3D flow behaviors when gas is injected into the cavity through the melt entrance or specific gas entrances. This software product predicts fingering effects and other gas injection molding issues to help you investigate the real production process and increase manufacturability.

Gas-Assisted Injection Molding (GAIM) visualizes 3D flow behaviors when gas is injected into the cavity through the melt entrance or specific gas entrances. This software product predicts fingering effects and other gas injection molding issues to help you investigate the real production process and increase manufacturability.

It also simulates the gas-assisted injection molding process when gas is injected into the polymer melt through a runner or other designed gas channels. The gas cores out a network of hollow channels throughout the mold cavity and drives the polymer melt to complete the filling process.

In addition, GAIM visualizes 3D gas penetration behaviors inside the cavity. This lets you evaluate the amounts of polymer injected into the cavity and optimize the size and placement of gas channels.

Capabilities

- Lowers filling and packing pressure and clamping tonnage

- Prevents sink marks and warpage

- Reduces residual stress

- Saves significant weight

- Shortens cooling time

Results

- Support for cooling and warpage simulations

- High mesh resolution for accurate analysis results

- Dedicated function for specifying the gas injected from single or multiple entrances or the melt entrance

- Dedicated function for stepping or poly-lining gas pressure control settings during the molding process

- Animation function for checking the filling dynamics

- Support for parallel processing to speed up calculation time