Moldex3D Encapsulation

The plastic encapsulation of integrated circuit components involves enclosing integrated circuits (IC) or chips in an epoxy molding compound (EMC). This is done through the transfer molding process to prevent physical damage and corrosion. However, several factors have made encapsulation a more challenging process. These include:

The complex chemorheology of EMCs

Electronic components with sophisticated and fine designs

Common chip encapsulation defects, including incomplete filling, voids, wire sweeps, paddle shifts, and package warpage

Moldex3D Chip Encapsulation addresses these problems by providing comprehensive 3D solutions that analyze the complicated physical phenomena inherent in the encapsulation processes. These solutions also offer enhanced design and process optimization.

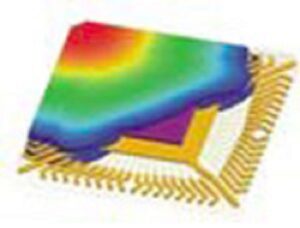

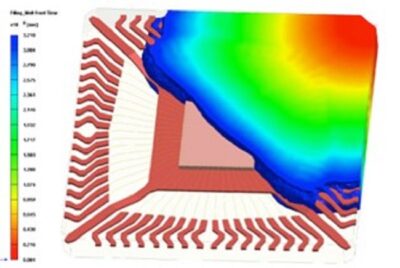

Melt front result after the mold was 45% filled.

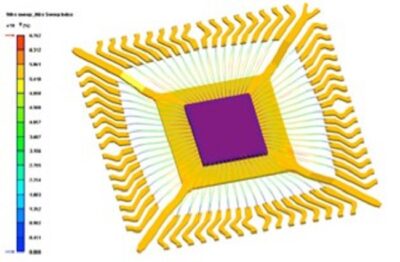

In a wire sweep simulation, deformed wires are compared and contrasted with the original wires and wire sweep index.

Reasons to Use Moldex3D Chip Encapsulation

- Provides innovative and complete tools to help you gain insight into plastic encapsulation processes

- Visualizes the thermoset resin filling and curing processes and their critical characteristics, such as warpage, wire sweep, and paddle shift

- Enables package and mold design validation and optimization to reduce manufacturing costs and design cycle time

- Offers simulation-driven design of complex and innovative IC packages

Capabilities of Moldex3D Chip Encapsulation for IC Packaging

- Enables the building of high-quality models through the use of a customized preprocessor for IC packages

- Provides the characteristics of parametric modeling and compatibility with comma-separated values files to help you save energy and time when building models

- Brings the complex rheology and curing reaction of EMCs into a simulation as an excellent solution for chip encapsulation process problems

- Visualizes the filling and curing processes, detects potential defects (e.g., air traps and weld lines), and optimizes runner and gate designs

- Visualize wire sweeps caused by the drag force of resin flow exerted on wires

- Prevents short circuits, broken wires, and other problems resulting from wire crossing

- Predicts paddle deflection caused by pressure drops during mold filling

- Calculates warpage by examining the correlation of components, resins, and their properties (e.g., the coefficient of linear thermal expansion of various materials and the pressure-volume-temperature-cure model of the molding compound)

- Brings flexibility and insight into products and the real-world performance of wire sweeps and paddle shifts with the help of structural analysis software