|

Cababilities

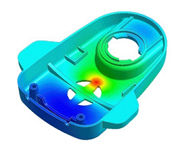

- Predicts melt front progression to see how a mold is filled

- Predicts 3D fountain flow phenomena, inertia phenomena, cavity effects, and viscosity heating effects

- Predicts weld line locations to minimize or eliminate them

- Predicts air traps

- Predicts injection pressure and evaluates clamping force requirements

- Evaluates runner layout and type to minimize material volume and achieve runner balancing

- Optimizes gate location and size to minimize weld lines and achieve balanced filling

- Optimizes process conditions in the filling stage, including injection time, melt temperature, ram speed profile, etc.

- Simulates filling processes for multi-cavity or family molds

- Simulates multicomponent molding processes, including insert molding and multi-shot sequential molding (Note: The MCM module is required for this.)

This software product’s explicit analysis capabilities give you a deeper insight into plastic flow behaviors, from macro to micro view. It includes fountain flow, inertia effect, and gravity effect. Flow can help you understand how melt flow progresses, identify where weld surfaces are, and detect short-shot problems.

This software product’s explicit analysis capabilities give you a deeper insight into plastic flow behaviors, from macro to micro view. It includes fountain flow, inertia effect, and gravity effect. Flow can help you understand how melt flow progresses, identify where weld surfaces are, and detect short-shot problems. Pack is one of our innovative

Pack is one of our innovative