|

|

|

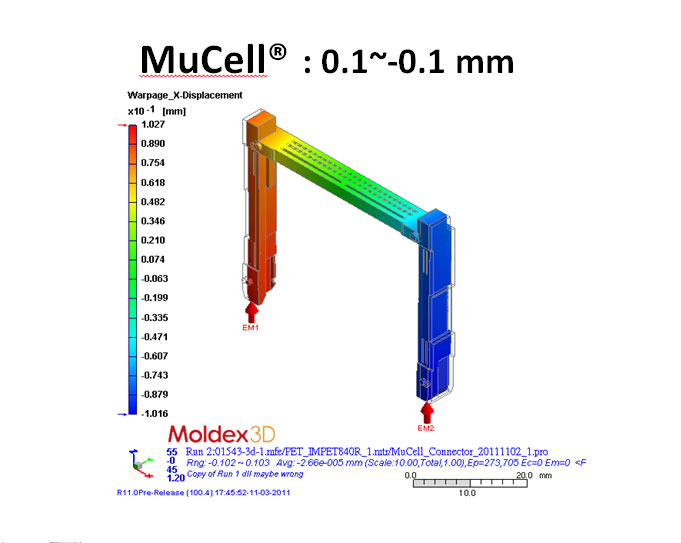

Microcellular Injection Molding – MuCell®

Through gas dissolution and nucleation, we improve the quality of your injection-molded plastic parts. This service also includes the following tasks:

Reducing Part Weight

Reducing Part Cost

Reducing Cycle Time

Reducing Pressure and Clamp Force

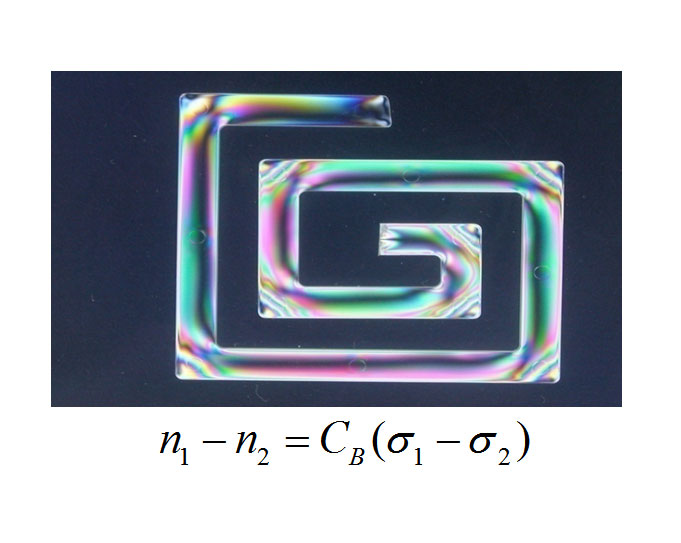

Reducing Stress Concentration

Reducing Warpage and Shrinkage

Improving Mechanical Properties

|

|